Announcements

-

Similar Content

-

Latest Posts

-

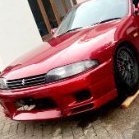

Meh, just saw the Nissan badge on the plenum on the thumbnail and presumed it wasn't as nasty a fake up as the paintjob.

-

It's most likely a 25, has vct and alloy cas, only 20 neo has vct but would have plastic cas

-

By TurboTapin · Posted

I ended up looking into this and you're absolutely right. The sport models with Syncro Rev Match(SRM) have a gear position sensor.

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now