Announcements

-

Similar Content

-

Latest Posts

-

Seems bang on to me , g30-900 will make 900 crank on e85(on paper). Deduct ~25% for 98 and you are at 675 crank. Run that to the wheels and fact you are only running 26psi you end up about your number. People forget how magic E85 is now that just about everyone is running it. "Back in the day" you had to be north of 30psi on a 850+hp turbo to get 600 at the wheels on 98.

-

By joshuaho96 · Posted

I can believe it if you're getting air into the pickup. Cavitation is tremendously destructive for pumps. -

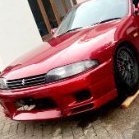

I think the pic in the first post is another car, and post 7 is OP's car with standard arms and swaybar swaybar swaybar. I can't tell what brand the silver coilovers are, and even if I could I don't know whether the spring rate is OK, if you can find a brand on the shocks and numbers on the springs that might help. Also, if you can measure the ride height from centre of your wheel to the guard that will help with advice too as handling suffers if ride height is too low

-

sadly, pics no work. that car must have spent a lot of time in a cryo bubble

-

By Murray_Calavera · Posted

In the first photo you posted, the colour of the control arms are the signature colour for Ikeya. Same for the swaybar, signature colour for Whiteline. I like Hardrace, they also do hardened rubber bushes if your car is mainly a street car. I like GKTech as well, but they use a lot of rose joints in their stuff so might not be the best choice for everyone. The system might have been good back in its day, but it's a prehistoric system now. I suspect that most people have removed the HICAS as they want the car to do what they want to do, not what the car wants to do. From what I also understand, it isn't consistent in it's behaviour on track so it's hard to trust the car/know where its absolute limits are for track use. Having said that, I think the HICAS eliminator kit was the first thing I installed when I bought my car. I don't personally have any experience with the HICAS system on a race track.

-

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now