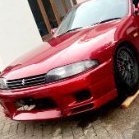

My 550whp v-spec R33gtr Needs help

Announcements

-

Similar Content

-

Latest Posts

-

Finished building and installing my stroked VQ25DET today. Came out to 2.771ltr. Built myself. VQ35 crank and forged rods, remaining parts are modified VQ25DET. Should I start a build thread ? Any Interest ?

-

Yep sure does . Comes on primes and cuts off as a factory pump would

-

By Dose Pipe Sutututu · Posted

And I hope the relay receives the trigger signal from the ECU and not the ignition power. It should prime and stop if the motor isn't running. -

I disconnected before the fuel pump and restriction still there. Disconnected at turbosmart fpr and also after ethanol sensor and pressure dropped. No kinks in line but I found one spot above diff that I can hear the fuel flowing while running so I'm wondering if there is built up corrosion from 10 years of sitting. I had injectors cleaned and tested and one was dead but rest were fine. Was never an issue when I owned the car previously but I'll talk to jez about his thoughts on if they should be changed to newer tech. Thx guys at least I know the setup should work again. Pump is wired directly to relay and not using factory plug any more

-

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now