jdmser

-

Posts

65 -

Joined

-

Last visited

-

Feedback

0%

Content Type

Profiles

Forums

Events

Gallery

Media Demo

Store

Posts posted by jdmser

-

-

1. PCV vacuum

2. Coolant to throttle body

3. Fuel Pressure Regulator vacuum

4. Coolant from plenum to coolant galley above injectors

5. Coolant feed to plenum

-

Just that one would have thought in the US there would be a lot cheaper options (hence me mentioning LS series motors) than building a RB24 motor for huge power, have you looked at exporting an RB30 bottom end from over here and using an RB25 head as another option?

If I end up splitting a bore on my RB24 the RB30 is what I'll do next. How far can they be bored out?

-

why not just use an LS1 if going for a dyno queen / drag car?

Also wouldn't an RB22 be the easiest and cheapest to build (probably not going to gain a whole amount out of it I guess)

If it were cheap or easy everybody would do it. I also have set my sights on the track six cylinder record and will be competing in the Sport Tuner Showdown Series. Neither of which can be done with a LS motor. As for power, I'll be running either a T67 or T76 Q trim with a 100 shot. Builder is pretty sure we'll see in excess of 700hp. But what does he know, he only won his class in this.

With a turbo Pinto motor. -

I ended up going ahead with a Rb24 build because things over hear are a little different. After leaning the motor out and burning up some rings and valves I thought about going with a RB25 or RB26. Over here RB25 motor sets are about $2500 US and RB26 engines are around $3000 US and then I'd need a RB25 trans for another $1000. Made more sense to me to work with what I had. We addressed the thin cylinder wall issue by filling the water jacket up the the freeze plugs. I'm not sure if the big end of the Tomei rods are bigger than the Eagles I used but, there was no need to clearance the bottom of the bores. If it takes up the 2+mm of clearance it has your motors done anyway. I have yet to see anyone post flow numbers for any of the RB heads. I know you can just look at the RB25 head and tell it flows more but, how many people use the flow of their head to it's full potential. A set a +1 valves, a port and polish, and a good set of cams and the RB20 head will flow plenty. I'm building a drag car/dyno queen so I've spent a little more than you have to. Things like coating main bearings, rod bearings, cam bearings, a pistons along with re-nitriding the crank after it was welded, ground and polished. I'm staying away of the forward facing plenums because nobody has provided enough info on their performance to justify spending the money. That and a 3" j pipe will be a go excuse for putting a 4" cowl hood on. Any who, I think I spent a little less then $3000 on all the parts to make the RB24 and then other $2500 in machining and head work. It's not as expensive over hear when you compared to what you would have to pay for a used RB25/26.

-

any update? how's it running so far?

-

If I was to do this again I would use something thicker than a single weave. As you can see some of the cardboard shows through but, that's only in pictures when using a flash. I day light you can't see it.

-

Here's a close up of the weave after the epoxy dried. I'll take a picture of the installed headliner tomorrow. This was my first project using carbon fiber. With a little more practice I'd like to start making things like intake and brake ducts.

-

I did a carbon fiber headliner recently for my Sentra. Turned out all right and didn't cost that much. Sure you could do the same thing to a metal hood if it was just for looks.

stripped off the cloth

rubbed off the foam

laid down a sheet of single weave carbon fiber and coated with epoxy resin

-

If you go with the Cometic the head and block both have to be completely smooth or it will leak.

-

I'll be running a 2mm thick Cometic mls head gasket until I have the combustion chambers reshaped. So, I can't o-ring or it's not going to seal. My builder runs 30+ on his motor without o-rings on a mls gasket and has no problems. As for the piston I think the 4agze piston are 81 or 81.5. The more meat you can leave in the bore the better.

-

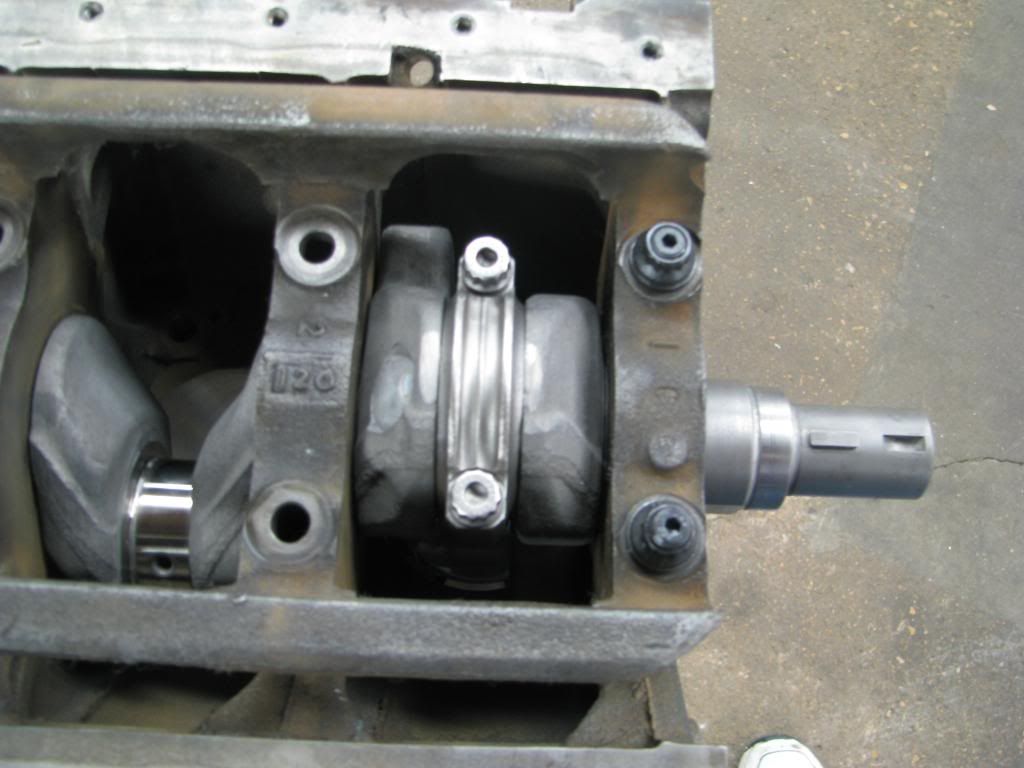

I'm in the middle of a RB24 build. I've found the RB26 crank with RB26 Eagle rods clears the block and girdle. It doesn't have a lot of clearance but, if the clearance goes away your motors already trashed away so who cares. After talking to my builder he would have rather seen me just put the crank in and keep it closer to stock bore than bore it to get the extra displacement. We ended up filling the block up to the welsh plugs to help strengthen the cylinder walls.

-

Just got my intake back. I like to do as much of my own work as possible but, had to send this out to be weld after I got it mocked up.

-

How well are you expecting that gate setup to work? Wouldnt mind doing the same for my car.

Doubt there will be any issue with it. It's right where it should be to get the best flow. A lot of guys do it over here after swapping RB engines into S chassis. It saves space which we don't have since the steering shaft in on the left side.

-

Been waiting on an exhaust valve for about three months now so I thought I'd clean up the engine bay a little. Keep in mind I'm neither a painter nor a welder.

My custom Cometic head gasket also came in.

-

Almost positive that someone flowed a set of their injectors and they were all over the place.

-

-

I've had my S14 for the last six year. About four years ago I swapped in a RB20 to replace the tired old KA24. Last August, almost a year ago now, I leaned the motor out due to a combination of things and lost compression in 4 cylinders. I ended up scoring the cylinders, melting the plugs, and ruining the rings. At this point I had a good amount of bolt on including a T3/TO4E, Sard 720cc injectors, chipped ecu, emanage, 3" custom down pipe, 3" 5zigen Border Max catback, fmic w/ custom piping, Zex kit for turbos, Q45 maf w/ JWT pop charger, N1 oil pump, JUN crank collar, Tomie procams, Tomie springs, and some other stuff I'm sure I'm forgetting. I knew the standard RB20 wasn't going to be enough for what I want to do with it so before the engine went I have begone collecting parts. In September after talking to a lot of people about machine work I finally picked an engine builder in the area that has expierence with small displacement turbo motors. He holds the record for the fast 4cyl at our local track. Here's his car

, it's a actually runs a Pinto motor.First thing we did is have the second hand R33 RB26 crank sent to be ground and repaired. It had a spun rod bearing so it had to be welded. To keep things simple we had all the journals ground to .25mm under so we wouldn't need to mix and match the bearings. Then the crank was nitrided again. While the crank was being repair we found that the spare head and block I had picked up for the build were cracked to I had to tear down my original motor and use the head and block from it. I ordered a set of JE custom pistons and got a good deal on a set of Eagle rods. The short block will be finished off with ACL race bearing and Total Seal stainless rings. The block was then decked and bored with a torque plate. We then filled the block with Hard Blok to the bottom of the freeze plugs and did the final hone.

Thinking about all the potenial this new build would have made me a little concerned about the driveline. So, I started looking into transmission options. I ended up getting a bell housing off of a GTR and mating it to the gear box out of a 2WD V6 Pathfinder. Alot cheaper than a RB25 transmission here in the states and very stout. For a clutch I went with a unit from South Bend clutch that used a modified 350Z pressure plate and a sintered iron sprung hub. It should be good for anything I can throw at it. I will also be getting rid of the oem two piece driveshaft and going with a steel one piece. I currently have a R33 vlsd for a rear end but, will be switching that out for a Q45 unit when I step up to a bigger turbo.

So far trying to do things the right way and buget the build have meant doing a lot of research and taking time. However, it's seems as though the end is in sight and the short block should be done by the end of next week. I am hoping to go after the current track record for 6 cylinders at the local track. It's only in the high nines right now so I think with the help of a T76 it could be doable.

-

I got a 3" inlet/outlet universal Catco off ebay for $35 shipped and had flanges welded on for another $20. Been running it for the last 4 years no issues. Can't say I felt any difference in power though since it's the only converter I've run.

-

got rid of my lag

-

I have been milling around the idea of doing a half fill in my RB24(bore RB20 not sohc) block. Is there anybody here that is running a filled block and what are water temps like? Can it be driven on the street?

-

The only reason you would need a 100mm throttle body is if you are making 800hp or more. I'd even say that 100mm TB is not needed until you tip over the 1000hp mark.

It's for a RB24 drag motor. I have two goals: single digit 1/4 pass and 750+whp. My builder seems to think 1000hp is do-able and I tend to believe him since he's making 800+whp with a Ford Pinto motor but, I'll be happy with 750.

-

Are these any good or are they junk?

http://cgi.ebay.com/NEW-UNIVERSAL-100-mm-4...A1%7C240%3A1318

-

Will the RB25 S1 throttle body fit on the factory RB20 intake manifold. My throttle shaft seal is leaking and I'm wanting to replace it with something a little better.

-

got any info and results and mix's they are running?

Here's a quote from a well known local tuner in reference to E85 "I love using alcohol on boosted applications. You can crank out an additional 10-14 more degrees of timing, and at an average of 7-10 rwhp per degree of timing, it adds up fast.". From what I've heard around here adding 1 gallon of E85 to a tank of 93 pump gas gets you somewhere around 95 or 96 octane and can help lean out a rich tune. I would imagine that's good for a degree or two. Most of the guys doing around here are either 03 Corbras or LSx F-bodies with superchargers, turbos, or big nitrous setups.

N1 Oil Pump - Epic Fail

in Forced Induction Performance

Posted

Just throwing my own little bit of fuel on the fire. I happened to have a N1 pump sitting around waiting to go back on my RB24 when it's done. I also happened to have a RB20 crank with a JUN collar installed that came out of my engine before it went to the builder. Took a little vid just to show the amount of play between the two. I also mic'd the two and came up with 0.22mm of clearance between the flats. Seems a bit excessive to me. I personally don't think it's a material issue as much as a design issue. And it's not just a pump design issue but, an entire oiling system design issue. I would bet that while not all of the N1 failures happen during heavy acceleration or cornering that the initial damage that leads to the failures did. I think that any kind of cavitation in the pump do to the oil sloshing to the back or side of the pan could cause extra resistance on the outside gear or even momentary seizure. This coupled with a loose fitting drive I would think would be enough to break the gears. I also think that has something to do with why Sydneykid prolly hasn't seen the failures that most have. If you do everything to keep the sump from ever sucking air this isn't an issue at all. When my engine gets back I'll have to fit the N1 drive gear to the R33 crank that's in it now and see if there's a difference. And just so it's clear, I'm not championing any pump or pump fix here. I'm just suggesting a cause to the problem.