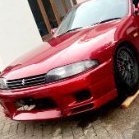

Almost Ready To Re Assemble Rb26. Need Some Advice

Announcements

-

Similar Content

-

Latest Posts

-

By shubby0901 · Posted

Its been a while! Finally thought to do something on this car, so here we go. This will be a slow burning, multiple posts as I spend 0.5-1hr a day on this job, over multiple days... Full set of GKTech suspension arms! Step 1: Buy Arms, done! Step 2: Start removing stuff. HICAS was easy. Rear suspension arms are now gone, they were a bitch but breaker bars with long handle extensions, 2 1.5hr slots later, stock arms are off! Next step, remove the hubs and take them to work to press out the bearings and bushings! -

I guess. The diff and the speedo are gearbox agnostic.

-

@GTSBoy sorry I still am unable to pm direct

-

So I'm.about rhe manual swap my 34gt sedan, I've already done a +T I'm just wanting to clarify that I'm not goin to need to do anything with a speed sensor on the box for the speedo to still operate as it is supplied a signal from the diff correct?

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now