-

Posts

3,723 -

Joined

-

Last visited

-

Days Won

1 -

Feedback

100%

Content Type

Profiles

Forums

Events

Gallery

Media Demo

Store

Everything posted by MrStabby

-

But he said the flapper is moving almost 90 degrees. Maybe try disconnecting the actuator so the gate will be blown full open and go for a run (with epic lag) to see if it still creeps up the top end. If so, the its a hot side/exhaust problem.

-

Film strength in a bearing is a product of viscosity and RPM, so heavy lugging at low RPM can be risky, but then the viscosity is higher because the oil is cold. Also, when the oil is cold, there can be less flow as the high pressure means that oil can be pushed pass the bypass valve to limit pressure, rather than being pushed through bearings etc. Interestingly flow at the pump does not have much effect on film strength, unless you get into starvation. If you heat a circular rod and circular hole made from the same material, the rod OD and hole ID will change the same amount. Forged pistons can expand more with temperature than cast block, so you need to take that into account when assembling the motor. Not sure if that's still the same problem it used to be - maybe they're tweaking the alloy's coefficient of thermal expansion to be more like cast iron? Anyone who still recommends a mineral oil these days has not kept themselves educated with how oill tech has changed. Fairly typical of older mechanics.

-

I read that stuff of Georges you posted and it agrees with the other info i've read. He does say "The "expensive" VI improvers are extremely shear resistant and when combined with a high quality synthetic base stock are synergistic", which was the point I was trying to make. I didn't specify "quality" oils as i should have, so there was some ambiguity. My starting point with oil is Mobil 1 since it appears to be a bang for buck winner (as long as you don't pay Australia tax). Also, remember that oils are continually being updated as they go through certs, eg SJ->SM->SN and change manufacturing methods eg PAO to GTL. Some time back Mobil 1 0W-40 showed shear is some motors, but these days people don't seem to be seeing it. The formulation improves over time, and the VIIs will become more shear resistant. I would follow Georges recommendations for that particular vehicle and year of recommendation, but for a different vehicle and as time moves on they will become less and less relevant.

-

The Viscosity Index (VI) of an oil depends on the combination of base stock and v/c polymers (aka viscosity index improvers (VIIs)). Do you have any URLs that show modern low VI oils lubricate better than modern high VI oils? I haven't seen that from what i've seen/read.

-

+1 Some guys like a smaller spread on the numbers based on the theory that the oil will be more shear resistant, but i think most oils are good enough now that its no longer a realistic concern.

-

Would be cool to find some biodeisel for it - ex french fry oil would smell pretty good

-

there's another thread http://www.sau.com.au/forums/topic/450147-r32-door-hinges-and-door-removal/ on replacing the hinges

-

Engine Manual Vq23de And Vq35de

MrStabby replied to KiwiRS4T's topic in Four Door Family & Wagoneers

PM me if you want to distribute via bittorrent, which is a good way to share the burdon of distribution. -

Is it still spooling up at the same rpm, or later? (might be collapsed cat).

-

Gts4 R32 Automatic Transmission Fluid

MrStabby replied to US Frank's topic in Suspension, braking, tyres and drivetrain

Nulon Synth ATF and Valvoline Synth ATF both have multiple Nissan certs. I'd use one of those. -

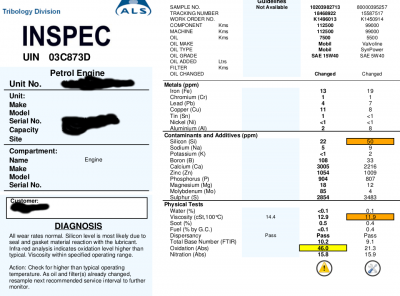

Oil sample #3 looking good at 7500kms. Oil is Mobil 1 0W-40. Viscosity is good, TBN is good, just some oxidation. I have noticed the temp gauge which is usually steadfast at about 2/5s has taken a few trips up to 3/5s for no apparent reason recently, and its been very cold in Sydney. Ill take a look at the cooling system and probably run the next to 7500.

-

From the album: Stagea

-

My track oil temp is under control. IIRC Mobil say M1 is ok with respect to degradation at 150 deg C. Agree that oil temp has a very important impact on oil life, as does quality of the oil. So whether you need to dump after a track day depends on those and other factors. As you say, if you dont test the oil you're just guessing, but thats fine too. I've been doing oil testing on the Stagea, and will do on the GTR next time.

-

I do scaling factor for track day kays - so any kms done on the track are multiplied by 5. So if i do 100kms at the track, that's equivalent to 500kms of regular driving. At this stage i have no evidence if this is sensible or not...

-

For Those Who Have Done The "twin Turbo" Pipe Mod

MrStabby replied to djvoodoo's topic in Engines & Forced Induction

+1, or even a flow check/pressure drop measurement of each. Downside could be lower bang for buck than some other mod, when using smaller non-shuffling turbos. Piggaz - would you do this on a car with stock turbos? -7s? -

Racepace Tein Vs Others

MrStabby replied to anon32's topic in Suspension, braking, tyres and drivetrain

Only thing I would change for the track is slightly harder springs as Josh suggested (surprise surprise, he knows his shit). but 10/6 is a good compromise for street comfort; the mrs doesn't mind riding in the GTR now - apart from the noise! also they respond to adjustments very predictably. I had some understeer which was easy to dial out by tightening up the rear shocks by one 'click' I'd love to know the theory behind how those spring rates work. Given who suggested it to you and the fact that i've heard of it before I guess i must be missing something. I've gone 10/8 -> 8/6 -> 7/6 on my 32 GTR and quite like the current setup so will leave it at that. From what I understand 10/6 should be an understeer monster, and shock adjustments would only help on short corners or right at the beginning of sweepers. Didnt Nismo go to same rate front and back to try to dial out understeer? Can anyone enlighten me? -

Shock Absorber Top Bushing Pair

MrStabby replied to zoomzoom's topic in Suspension, braking, tyres and drivetrain

I would just take to old ones along to see if there's anything generic that matches closely enough at a supacheap/repco etc. If there's nothing there try a suspension shop. A little smaller in OD wouldn't be a problem if there a stiffer material than the stock bit. -

Npc Performance Clutches! Thumbs Up!

MrStabby replied to Yeedogga's topic in Suspension, braking, tyres and drivetrain

Oi! No nit picking or we'll have to start talking about moments of inertia. -

In the 32 GTR i get full coolant out the bleeder by just topping up the radiator. BOVs are designed to vent off the air that would otherwise slow the turbo down after the throttles shut. So if you have one you should produce boost more quickly after gear changes.

-

Npc Performance Clutches! Thumbs Up!

MrStabby replied to Yeedogga's topic in Suspension, braking, tyres and drivetrain

AFAIK there's no upside to using a smaller diameter clutch, so i'm guessing everyone's using the 10. That's the one i'm using. -

Too thick for an RB with standard bearing tolerances. You'll just be pushing a lot of oil through the filter bypass and relief valves.

-

Npc Vs Jim Berry Vs Nismo Copper Mix

MrStabby replied to anon32's topic in Suspension, braking, tyres and drivetrain

And the twin C spec coppermix twin plate: Standard pull is : 3002B-RS599 ( After 93 ) coppermix twin plate: Standard push is : 3002A-RS594 ( Until 93 ) coppermix twin plate: C-spec pull for GTR32 is : 3002B-RR598-C ( After Feb 93 ) coppermix twin plate: C-spec push for GTR32 is : 3002A-RR593-C ( Until Feb 93 ) -

Wheel Alignment And Back End Handling Issue

MrStabby replied to dori34's topic in Suspension, braking, tyres and drivetrain

Yeah rear toe out will make the rear unstable. So get the slop out then set it to zero. You said "rear hicas arm" but there's only one hicas arm each side (no front/rear) so double check your understanding about the arms. There is a ball joint that looks like a tie rod end on the outer end of the hicas arm, dont know whats on the inside but i'm guessing its similar. If any of the other ball joints are loose get them replaced too and do them all at once, before you get the next alignment. The KPI / included angle statement sound bogus because that would mean you have two bent hubs. If you're anywhere near Tempe go to Heasmans. -

Some would say they are the single most important thing to consider when selecting oil. They specify the range of viscosity, eg a -30 can be 9.3-12.5 and a -40 can be 12.5-16.3 at 100 degC.