-

Posts

1,355 -

Joined

-

Last visited

-

Feedback

100%

Content Type

Profiles

Forums

Events

Gallery

Media Demo

Store

Everything posted by GTRPSI

-

Rb30 Crank Durability And Harmonic Balancer

GTRPSI replied to Chids34's topic in Engines & Forced Induction

Its there, its real on RB30's its been seen and documented for a long time. However its at certain RPM's in varying degrees, for example you may have one at 7640, a smaller one at 7980 and maybe a huge one at 8140 etc. The point being is your not sitting at that exact RPM, you rev through it, doing so its just a slight harmless bleep while transitioning through. Hold it at exactly the right harmonic point for long enough and expect the engine to be tearing itself to sherds....your just passing through it which does not leave enough time for anything to happen. I have discussed this between quite a few big HP RB30 drag engine builders (1000Hp+) and none have had issues with it however all have agreed if you sit there long enough at that sweet spot it wouldn't be a good thing. Who holds a engine at exactly 1 high RPM? (and it happens to be that right harmonic spot) While on the subject, many different engines have a inherent harmonic issues due to design, i remember Cosworth having one with their Turbo F1 design and simply giving up on the engine and taking it back to the drawing board. -

Why bother....OK apart from Legality (which aftermarket turbos still dont cover you for).....

-

Concentrate on equalizing between crankcase and under rocker cover pressures, point being is you want less (ideally) or the same pressure in the crank case than in the cover. A large enough fitting running from the crank case to the rocker cover does most of the problem solving, once you stop allowing blowby to run up the engine via the oil return passages, oil can naturally find its way back down. Most times this is solved by either running a pipe or 2 between the crank case and rocker cover or by venting the crank case straight out to a catch can. If you want to assist the catch can in pulling out crank case pressure out of the bottom end, run its outlet or breather into the intake pipe between the air filter and turbo, its a natural vacuum producing point thats free to use.

-

Next time it happens, hold the relocation assembly steady with a large shifter on one of the oil line fittings while turning the filter, most people do it that way when its difficult.

-

Tail Shaft Tolerance Looking For Some Advice

GTRPSI replied to Franko07's topic in Engines & Forced Induction

Do Cefiros have a floating diff or is it fixed into a subframe? Point being is you need some clearance in a floating diff setup as the driveshaft moves in and out however in a subframe mounted diff setup there is no (almost no) diff movement, in these cases best to follow the old seal wear pattern on the yoke. Its possible to make a machined billet spacer to fit on the diff side and use longer bolts to push the tailshaft forwards if need be however the most reliable way would be to get a longer tailshaft made up. -

Hone finish should be based on the ring manufacturers recommendations. Bore to piston clearance should be based on the piston manufacturer. Seal pro do make 1.2 comp and 2.5 oil rings. Most off the shelf packages are 1, 1.2 comp and 2.8 oil, some are 1.2 1.5 and 2.5 or 3mm oil. They can put together whatever you need, give them your ring thickness package and bore and bobs your uncle..... Last time i needed a set of 1, 1.2, 2.8 seal pro rings the were around $150-$200 to my door for a RB26.

-

What Machine Shop In Sydney Has A (hone) Rb26 Torque Plate

GTRPSI replied to GD51LA's topic in Engines & Forced Induction

Most half good workshops will have one, they use their old RB30 plates which have the bolt holes drilled out to take RB26 bolts through them. -

Most likely a vacuum/boost leak. Last time i had a miss it was the igniter module, in my case it was above 3500 but sounded like the wide spark gap or faulty coil pack issue. In your case with backfire it sounds more like a Vacuum or boost leak, you need to check your hoses and pipes first.

-

Bet you it spun a bearing. Now the scary thing is who built the engine and if it did spin a bearing did they machine or use a new crank.

-

How To Fill Empty Engine Block With Coolant

GTRPSI replied to re34perGTT's topic in General Maintenance

Just pour coolant in like normal, most thermostats have a small air bleed hole. When your warming up the car, the thermo will open, water level will drop and you add coolant. Then follow the standard bleed procedure, open the bleed nipple when hot to purge out any air pockets in the head. Should all be in the workshop manual..... -

Longer Oil Pick Up With Rips Extension Sump ?

GTRPSI replied to cobrAA's topic in Engines & Forced Induction

Dont muck around asking others and relying on guess work, it takes 5 minutes to check and know. Flip the engine upside down, cover the oil pickup in glad wrap, put a mound of playdough on the pickup and mock fit the sump on. (dont need to tighten any bolts) Remove sump, slice playdough open on pickup with a sharp blade to check thickness which is your pickup clearance. Then add or remove pickup pipe to adjust as wanted. If you have a trap door sump, its also good to check that the pickup is centered to the trap doors. In my case it was too close to the rear door making it almost impossible to open, i had to move the pickup a little forward towards the sump. -

A balanced stock crank will take far more than what most believe. RIPs is turning standard factory RB30 cranks to over 10,000RPM and holding well over 1200+Hp reliably. Similar reports with factory RB26 cranks. The biggest limitation when using aftermarket forged rods and pistons is the rod bolts and pins used, from there the distortion of the bores is a major player, thats why people use part grout fills, most block cracking between cylinders 3 and 4 is from the front diff forces on launch going through the block. How many have seen a RB crank that was crack tested actually snap? And if so was it the crank material strength itself that caused it? Think about it......

-

Turbo Install, Cut Fuel Or Ignition?

GTRPSI replied to re34perGTT's topic in Engines & Forced Induction

Seriously people build engines without worrying about it, within a second or 2 of starting your whole engine gets oil pressure, some just squirt some oil in before fitting the oil line on. If you want to sit there cranking it, remove the spark plugs to make cranking easy and it automatically kills spark and kicks out any injected fuel out through the plug holes. -

5mm sag, and possibly your shockers have worn some too allowing more freedom for the suspension to travel further. Seen people stop rubbing by hardening the shocker settings instead of harder or longer springs in the past. Not the right way to do it obviously but pointing it out as your springs have only sagged 5mm but shockers are also known to wear.

-

I had a old engineer mate who around 25 years ago fitted a supercharger to his Datsun 1600 after bringing in 2 supercharges from the US for fun. He ended up rigging up a direct water injection setup to help control Det, it simply consisted of a wiper bottle and its pump, a home made jet, relay and a switch hooked onto work from the accelerator linkage when near full throttle, tubing was solid copper to the manifold and plastic to the bottle to allow for movement.. This is back in the day of carbs and distributors with points, took him a bit of playing to find the right jet through experimentation, it ended up running for years on 1 Bar, last time we spoke on the phone about 2 years ago, he still had it, engine was fine just the shell had started to rust on him.

-

There is heaps of room to tap down restrictors and add other smaller (but not larger) ones. If going larger you need to remove the smaller one in there, i use a self tapping screw run into the hole of the old one and use a old shifter to tap it out. If the block is stripped i always remove them no matter what as dirt can get caught under them, very important to do so when dealing with spun bearing engines so you can get the rifle cleaner rods inside for scrubbing.

-

Adding Rb26 Windage Trays To Rb30 Girdle......

GTRPSI replied to Ramius83's topic in Engines & Forced Induction

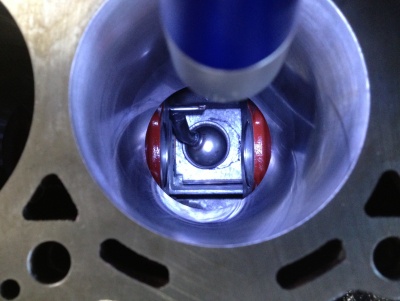

It ties the bottom end main caps together exactly in the same way as the drilled factory RB26 one does, no weaker, no reported cracks of failures what so ever. The rails only take fore and aft stress to tie the caps together. A pic where you can see part of mine done.... -

And while your there with the head off get it pressure tested.

-

Have you pulled the plugs to check for water ingress? Is the water level actually dropping? Are you 100% positive that your RPM breakdown is a head gasket or are you jumping to that conclusion? (I seen heads get pulled off before where it wasn't the head gasket at all) If all else fails and it is the head gasket, something will be warped or the deck finish on either surface is too rough. Could also be in the tune, E85 is good at taking timing and boost however at those cyl pressures less knock will be more damaging as its at higher pressures.

-

More like the later BF models through to FG models got the F6 engine. Still the valve springs are fit and miss.....even FG owners are upgrading springs to go over 300Kw.

-

I missed you thread post but rear left in boot is a common location for a oil tank.....maybe consider moving it there.

-

PM me and ill tell you how to make them, they are not available locally in Aus but can be made "new" from another rotor size with some basic machining. A engineer should be able to knock them up cheaply from another rotor part number that's 99% of the way there to fit. Its a regular issue we see......

-

Try 50 weight, should fix it if running a 30 weight currently, the thickness you run depends on the clearances used, if its worn run a thicker oil, our clearances are set up for a 60 weight of oil. Sure your bypass is not stuck open? Have not heard of spring washers being used before, flat ones yes. Thicker oil will bring the pressure up and open the bypass earlier.