Announcements

-

Similar Content

-

Latest Posts

-

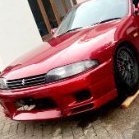

Did some baking today, managed to fit it all in the oven. Turned out pretty good. Hopefully it holds up well to a bit of tool abuse. Popped a few pieces on to see what the colours will look like. Pretty happy with how it came up. Now to wait for the rest of the stuff to rock up

-

Connect casually with like-minded individuals on the ultimate dating platform. Authentic Maidens Exemplary Сasual Dating

-

A creative mounting location would be from the roof. We totally need to bring back ludicrous stereo designs from AutoSalon days...

-

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now