Announcements

-

Similar Content

-

Latest Posts

-

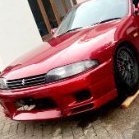

You are wrong. That's just Whiteline going along with the incorrect slanguage of the sheeple userbase. They are only correctly known as anti-roll bars. They are only incorrectly known as swaybars. They do do anything to prevent "sway". The swaybars that are fitted to trailler hitches do prevent sway. In the trailer. And they do not look like anti-roll bars. So, take your incorrect infopinion away.

-

https://whiteline.com.au/front-and-rear-sway-bar-vehicle-kit-to-suit-nissan-skyline-r32-awd-9986-bnk009.html whiteline calls them a sway bar, the topic of this post.

-

By Dose Pipe Sutututu · Posted

Yep, somehow noone wants to fit anti roll bars these days to their cars lol. -

Two layers of race tape on the brake duct. One piece of split firesleeve, silicone hose or something similar (and 2x cable ties) on the brake hose. Boost off into the sunset and stop caring about it. Until the inspection 6 months later, that is.

-

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now